The suspension polymerisation process is most widely used process tomanufacture PVC.

First, the raw material VCM is pressurised and liquefied, and then fedinto the polymerisation reactor, which contains water and suspending agents inadvance. Through high-speed agitation within the reactor, small droplets of VCMare obtained. Next, the initiator for polymerisation is fed into the reactor,and PVC is produced by reaction under a few bar at 40 – 60°C.PVC obtained through suspension polymerisation is suspended in water asparticles of 50~200 μm diameter (in slurry form). Thereafter the slurrydischarged from the polymerisation reactor is stripped of residual monomer,dehydrated, dried and the particle size controlled by screening to yield PVC inthe form of a white powder. The un-reacted VCM is entirely recovered throughthe stripping process, and after purification, recycled as raw material forreuse in this process. PVC resin produced via this ‘suspension’ process isreferred to within the industry using the abbreviation S-PVC.

Emulsion polymerisation and bulk polymerisation are alternative, much lessextensively employed, technologies to manufacture PVC. Emulsion polymerisationproduces finer resin grades having much smaller particles, which are requiredby certain applications. This type of resin is sometimes called ‘paste’ PVC andreferred to within the industry using the abbreviation P-PVC to distinguish itfrom S-PVC.

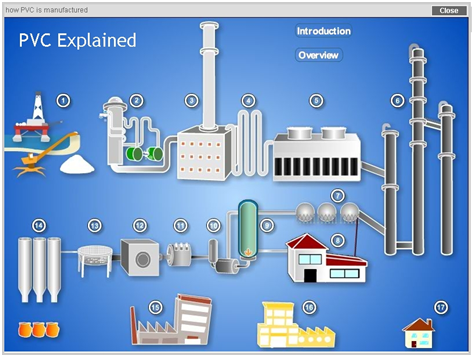

Click the diagram for an interactive animation showing how PVC is produced.Once the diagram has loaded click any section to see part of that process or onthe OVERVIEW to watch to all sequences.

Get Social